Test Systems

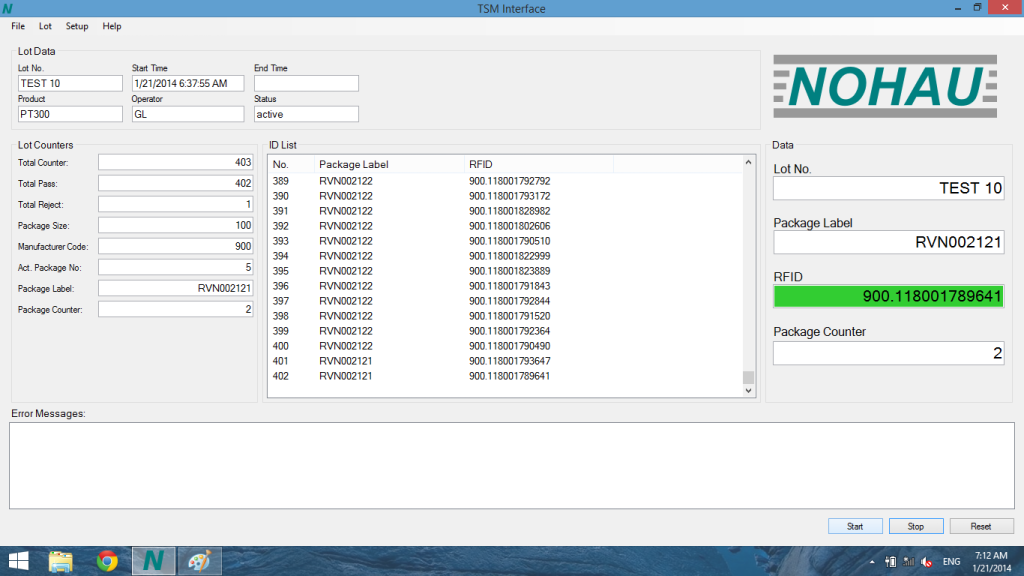

Transponder test system, type TSM02

Our transponder test system TSM02 is a benchtop device for testing glass transponders for their function and ID. The transponders are automatically transported to a test point and read out by an RFID antenna. The distance between the antenna and the test point can be adjusted, so transponders can be sorted out with too small a reading distance.

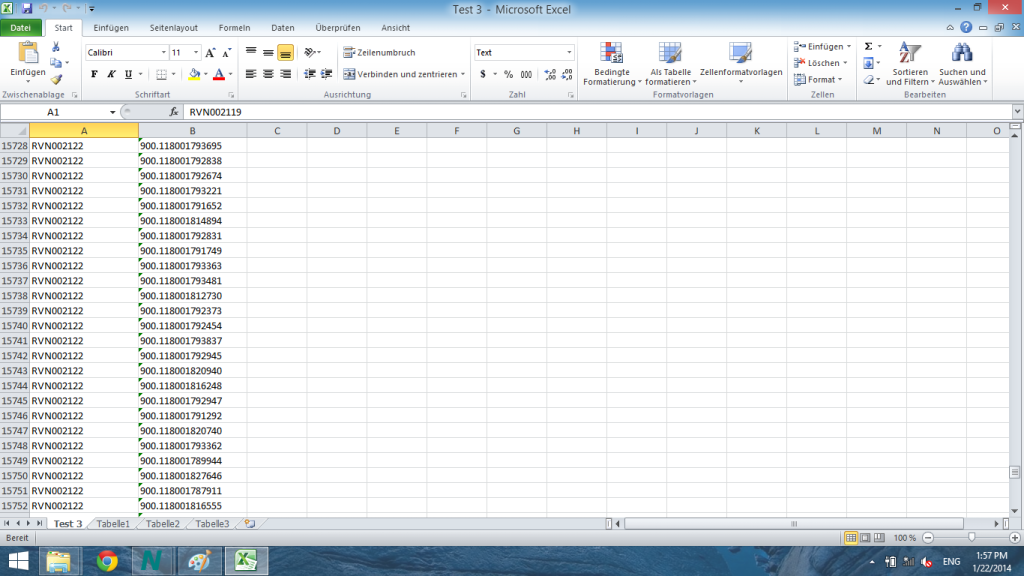

Each capture ID is checked and compared with the default manufacturer code. If desired, further examinations or a comparison with an existing database can also be carried out. The data of the valid measurements are stored together with the lot number and the number of the packaging unit and can be exported as an Excel spreadsheet.

If a transponder has no read function or has an invalid ID, the system stops and the transponder can be removed from the process.

The system stops at the end of a programmable size of the packaging unit. A barcode scanner is installed on the device and allows the number of a new packaging unit to be easily read in. The system can thus read, check and store more than 2000 transponder numbers per hour.

The device comes with a laptop (Windows 8 and Windows Office) and a suitable transponder reader. Optionally, a reader of your choice can also be installed.